Research Focuses and Thrusts

#1. Metal Additive Manufacturing

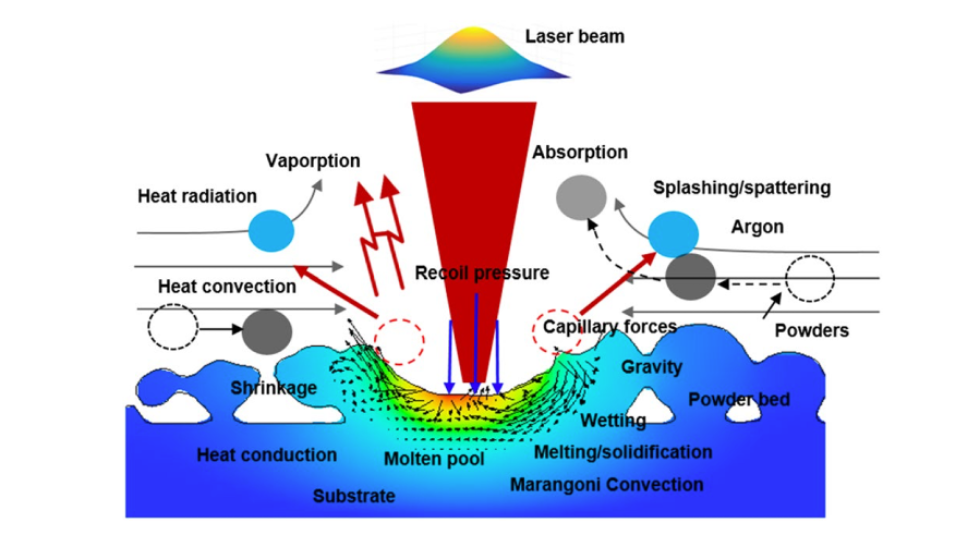

Illustration of L-PBF (Chen et al., 2018, Applied Phys. A)

Illustration of L-PBF (Chen et al., 2018, Applied Phys. A)

Laser Powder Bed Fusion (L-PBF)

Laser Powder Bed Fusion (L-PBF) is a metal additive manufacturing process in which a high-power laser selectively melts thin layers of metallic powder to build complex three-dimensional parts layer by layer. The process inherently involves granular media dynamics, from powder spreading and recoating to particle-scale heat transfer, melting, and vaporization, making it a rich domain for coupled granular-fluid and multiphysics research. Understanding and controlling the interaction between the laser, powder bed, melt pool, and vapor phases is essential to mitigate defects and ensure part quality.

High-Fidelity Multiphysics Modeling of Laser Powder Bed Fusion

Our Lab has developed and applied an advanced, high-resolution semi-coupled resolved CFD-DEM (Computational Fluid Dynamics - Discrete Element Method) framework to model the complex multi-physics phenomena in L-PBF. This tool integrates discrete powder dynamics, multi-phase melt pool flow, vaporization, condensation, and solidification within a unified simulation environment, incorporating a VOF-compatible ray-tracing laser model and advanced phase-change sub-models. Read the 2021 and 2022 paper.

Coupled CFD-DEM modeling of L-PBF

Coupled CFD-DEM modeling of L-PBF

High-fidelity simulations of keyhole and multiphysics in L-PBF

High-fidelity simulations of keyhole and multiphysics in L-PBF

Shown above is a high-fidelity simulation of the melting process of Titanium alloy Ti-6Al-4V powder using the proposed CFD-DEM framework. Our model successfully captures several critical physical phenomena, including melt pool dynamics, deep keyhole formation, high?speed vapor ejection from the keyhole, and the resulting ambient gas vortices that entrain and disperse surface powder particles, leading to spattering and scattering. The simulation also accounts for multi-way phase transformations, such as the melting of solid powder grains into liquid metal, the vaporization of melt into metallic vapor, and the solidification of the melt pool into a consolidated track. Using this tool, we could further work to uncover the fundamental mechanisms of keyhole pore evolution and to formulate adaptive process control strategy for active defect suppression in L-PBF.

Uncover the mechanisms of keyhole pore dynamics

Using the high-fidelity simulation tool developed, we have conducted comprehensive investigation into the lifecycle of keyhole instability and keyhole-induced porosity to uncovers new physics and understanding. Our study found that the dynamic instability of the keyhole and the subsequent evolution of pores are governed by five interdependent factors: vapor condensation, liquid vortex, recoil pressure, surface tension, and keyhole morphology. A central finding establishes vapor condensation within an enclosed pore as the primary driver for generating high-speed microjets, which directly cause pore collapse and splitting. This mechanistic understanding led to the classification of three pore deformation regimes based on the condensation rate: "splitting and leaving," "shrinkage and leaving," and "shrinkage and capture," and proposed condensation control as a pathway for pore elimination. Read this AM paper.

Modeling of keyhole pore dynamics

Modeling of keyhole pore dynamics

Physics-based adaptive control to avoid keyhole pore formation

Building upon these core discoveries, subsequent research has established a mechanism-based optimization strategy using adaptive laser power. The keyhole pore formation process is delineated into five stages: "J-like" keyhole formation, keyhole closure, pore collapse, pore splitting, and pore motion. Analysis indicates that reducing laser power at the onset of the "J-like" keyhole formation stage is an effective method to stabilize the keyhole and prevent pore generation. To facilitate real-time control, adaptive indices were developed to quantify keyhole fluctuations from 2D imaging data, forming the basis of an optimization criterion. Parametric studies demonstrate that a strategy employing a moderate laser power reduction at a judiciously selected threshold can effectively suppress expansion-induced pore formation while maintaining high manufacturing efficiency. We are committing with industrial partners for practical application of this powerful prediction tool. Read this AM paper.

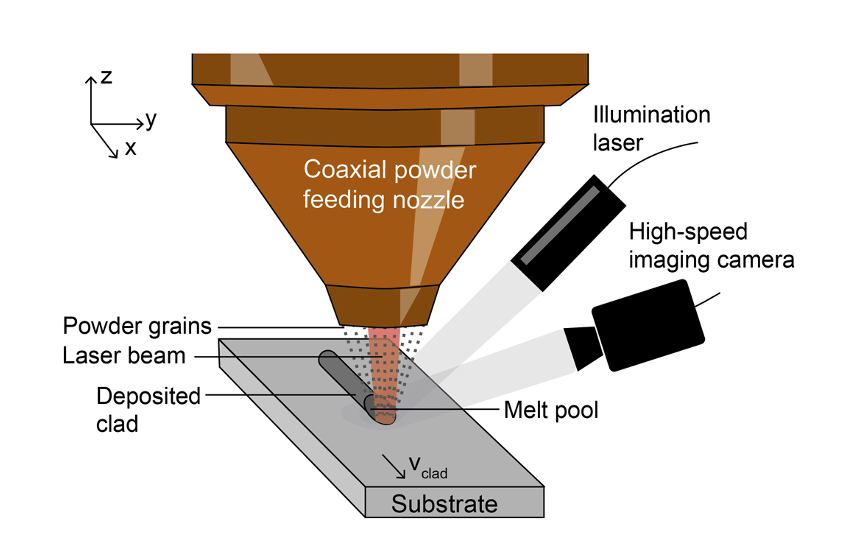

Ongoing: Powder-based Direct Energy Deposition (PB-DED)

Powder-based directed energy deposition (PB-DED) has emerged as a promising additive manufacturing technology for large-scale metal components, yet its process fidelity is plagued by the complex interplay of particle-laden flow, laser energy distribution, and melt track hydrodynamics. Our ongoing effort is to further extend our tool developed for L-PBF to a novel semi-resolved Computational Fluid Dynamics and Discrete Element Method (CFD-DEM) coupling scheme that could address these limitations for high-fidelity simulations of PB-DED.

Stay tuned and visit back!

Direct Energy Deposition for Additive Manufacturing (Naesstroem et al., 2021)

Direct Energy Deposition for Additive Manufacturing (Naesstroem et al., 2021)

#2. Realistic Particle Shape Modeling

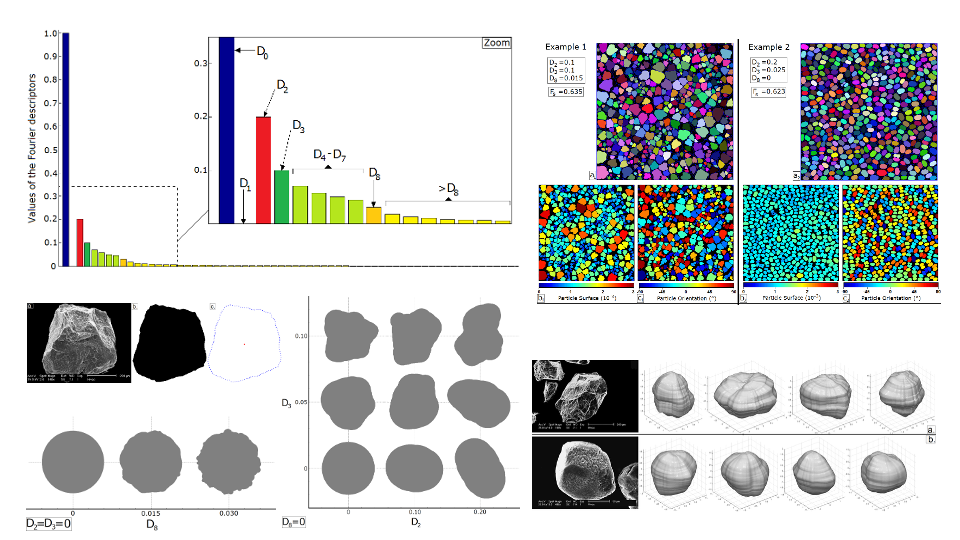

Fourier Shape Descriptor Method

Recognizing that realistic particle shape, encompassing features such as elongation, flatness, angularity, and asymmetry, profoundly influences the mechanical behavior of granular assemblies, Dr Guilhem Mollon (now INSA Lyon) worked with me to introduce a unified, data-driven framework for generating and utilizing realistic particle shapes in discrete element modeling (DEM) of granular media in 2011. Central to this approach is the use of Fourier shape descriptors (FSDs), statistical signatures derived from 2D projections of real sand grains, as generative tools rather than mere characterizers. By preserving the amplitude spectrum of FSDs while randomizing phase angles, the method produces ensembles of particles that are geometrically diverse yet statistically faithful to natural sands. This technique is first implemented in 2D (VoronoiFSD paper), where FSD-based particles are embedded within a constrained Voronoi tessellation calibrated via an improved Inverse Monte Carlo (IMC) algorithm to match target grain size distributions, fabric anisotropy, and solid fraction. The framework is then extended to 3D (3DFSD paper) through a novel morphing technique that combines orthogonal cross-sections into star-like surfaces, with a critical correction factor applied to reconcile discrepancies between 2D projections (used for FSD calibration) and true 3D cross-sections, validated against SEM imagery of real sands.

Our Fourier shape descriptor (FSD) method laid the foundation for subsequent 3D particle modeling approaches, such as Spherical Harmonics. Its practical value is demonstrated in hopper flow simulations (read hopper flow paper), where realistic grain shapes produce upward-propagating radial waves in coordination number, velocity, and stress that show signatures of intermittent arching and force-chain collapse, while void ratio fluctuations remain uncorrelated, challenging the notion of "density waves." The work establishes particle shape as a controllable microstructure parameter that governs macroscale behavior, bridging experimental characterization with computational mechanics to enable predictive, physics-informed discrete modeling of granular media.

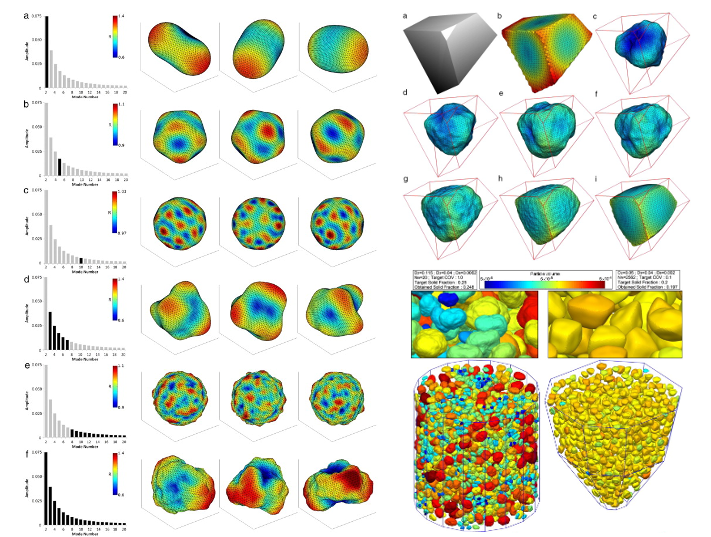

FSDs + 3D Random Gaussian Field

However, our early FSD-based 3D method suffered from artificial anisotropy and could not reproduce planar facets common in natural sands. Our following 2014 CMAME paper resolves these limitations by introducing a rigorous 3D random field formulation on spherical topology, where particle surfaces are represented as correlated Gaussian random fields. Critically, the authors develop a novel spectral-to-spatial mapping that ensures the resulting covariance matrix is positive definite while preserving the frequency content of the input FD spectrum. This allows for true isotropic 3D shape generation, where low-order modes control elongation and global irregularities, and high-order modes govern surface roughness, now without directional artifacts.

This mature 3D framework is seamlessly integrated with Constrained Voronoi Tessellation to pack particles into arbitrary containers while controlling size distribution, solid fraction, and fabric anisotropy. A key innovation is the introduction of a shape-fitting parameter that aligns particle morphology with the geometry of its Voronoi cell, enabling dense, facetted packings unattainable with purely random shapes. Together, these series FSD papers form a cohesive pipeline: from experimental image &rarr FD spectrum &rarr statistically faithful 3D particle &rarr controlled packing &rarr physically insightful DEM simulation. This paradigm shifts discrete modeling from idealized abstraction to quantitative, morphology-aware prediction of granular behavior.

3D Random Gaussian Field enhanced FSD for shape modeling

3D Random Gaussian Field enhanced FSD for shape modeling

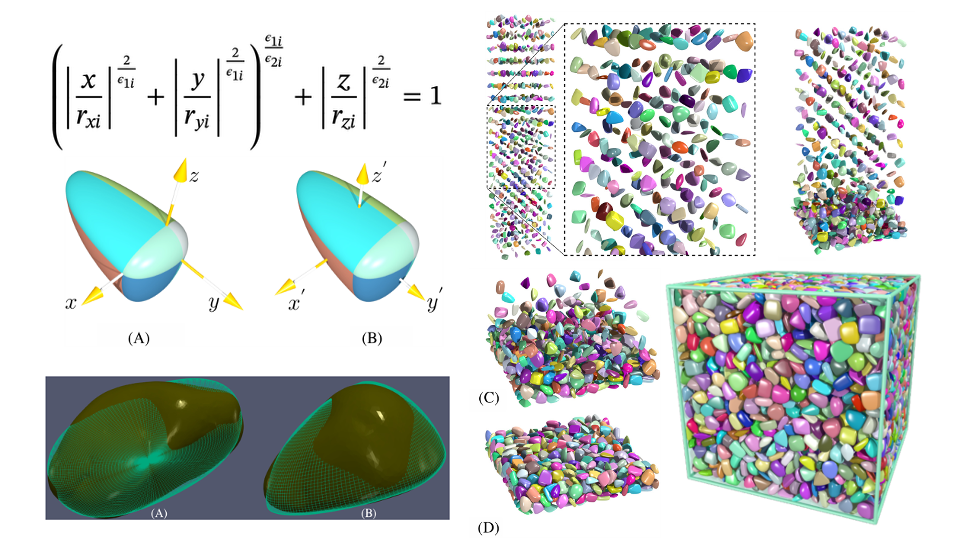

Poly-superellipsoid-based approach

We have further proposed a poly-superellipsoid-based approach on particle morphology for DEM modeling of granular media (Read the paper). This poly-superellipsoid framework unifies geometric versatility with computational efficiency. Unlike conventional approaches that rely on clumped spheres or complex NURBS representations, the poly-superellipsoid uses only eight shape parameters to describe a broad spectrum of convex particle morphologies. This compact parametric representation enables accurate fitting of real particle geometries, such as those derived from CT scans, while avoiding the excessive computational cost associated with high-resolution clump models.

A key original contribution lies in the development of a robust and efficient contact detection algorithm tailored to poly-superellipsoids. We introduced a hybrid approach that combines the Levenberg-Marquardt (LM) optimization method with the Gilbert-Johnson-Keerthi (GJK) algorithm, leveraging the strengths of both: LM provides rapid convergence for general contacts, while GJK ensures robustness in degenerate cases (e.g., flat face-to-face contacts). Built upon the common-normal contact concept and supported by an analytically defined support function, this algorithm enables accurate computation of contact geometry, including penetration depth and contact normals, for arbitrary convex shapes. The method is validated through rigorous numerical tests and demonstrated in large-scale simulations of granular packing and triaxial compression, showing that particle shape directly governs macroscopic responses such as shear strength, dilatancy, and fabric evolution.

SudoDEM Open-source Code

Based on the poly-superellipsoid framework, We have further developed SudoDEM, a next-generation discrete element method (DEM) code with full functionality for modeling both 2D and 3D non-spherical particles. SudoDEM provides a comprehensive library of primitive particle shapes, including poly-superellipsoids, superellipsoids, cylinders, cones, and polyhedra in 3D, as well as disks and superellipses in 2D, and is further accelerated via OpenMP parallelization. The code features highly efficient contact detection algorithms specifically designed to robustly handle interactions among complex-shaped particles. Full features of SudoDEM are summarised in our CPC paper .

SudoDEM has been made open-source for the community to free download and use: https://sudodem.github.io.

Beyond geotechnics, the poly-superellipsoid framework offers broad interdisciplinary potential. In pharmaceutical manufacturing, it can predict tablet compaction and segregation by capturing particle morphology. In additive manufacturing, especially laser powder-bed fusion (L-PBF), it improves predictions of packing density, thermal conductivity, and defects. In chemical and food engineering, it enhances the design of fluidized beds, mixers, and hoppers by modeling shape-dependent flow and segregation. Its mathematical compactness and computational scalability (with OpenMP support) make it ideal for multiphysics integration, such as fluid-particle or electrostatic coupling, laying a versatile foundation for physics-informed digital twins of particulate systems across science and industry.

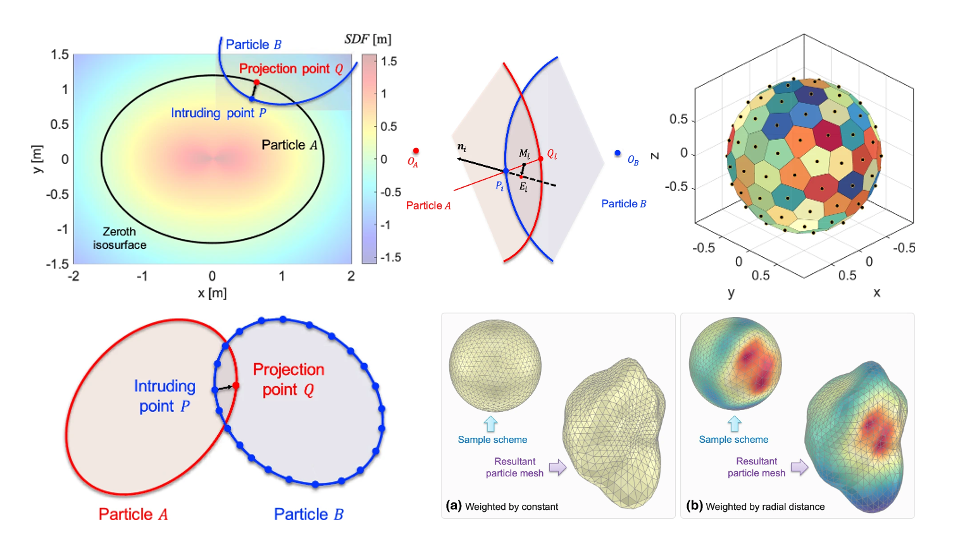

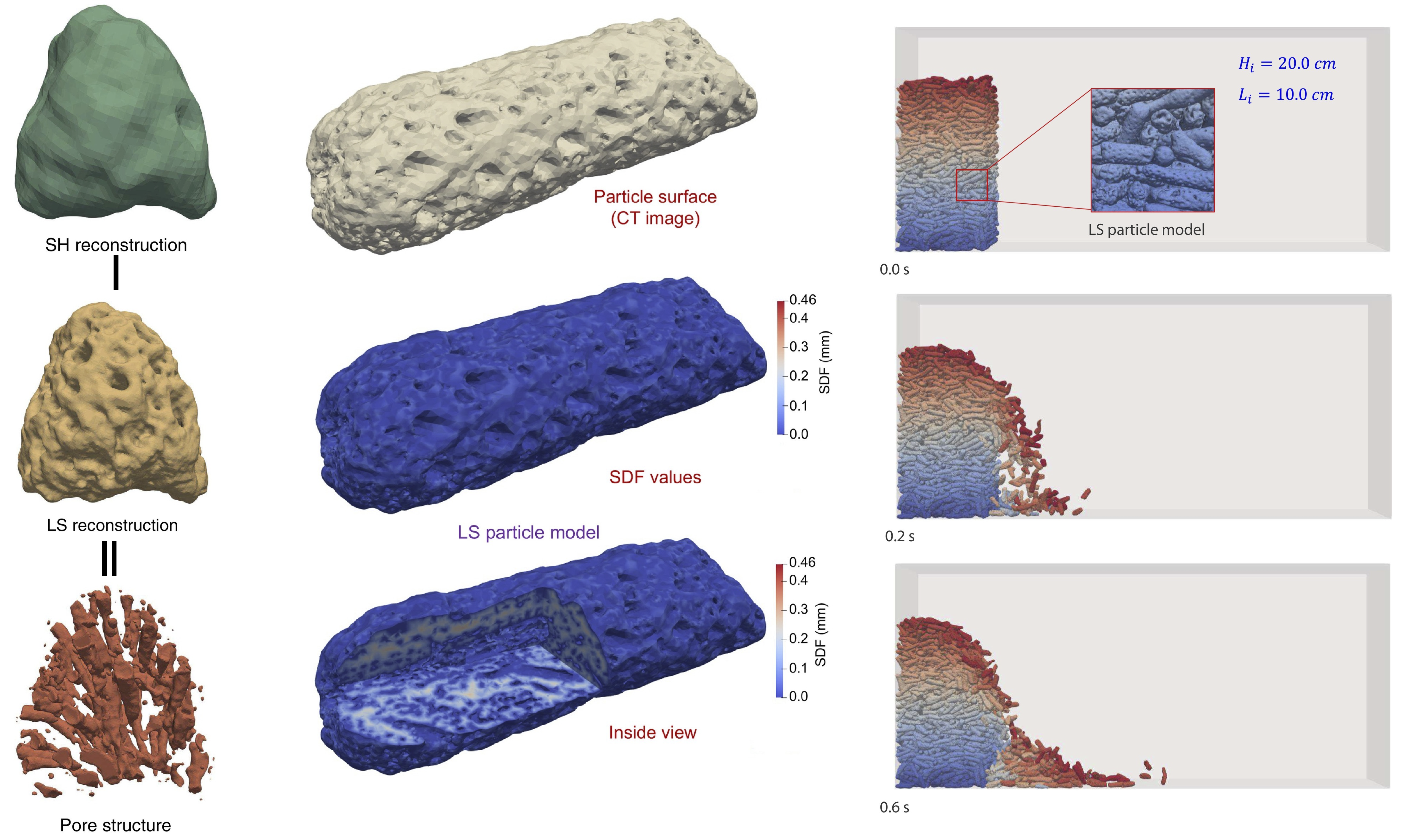

Signed-Distance Field (SDF) DEM

We have recently proposed a unified Signed Distance Field (SDF)-based framework for DEM modeling of granular media with arbitrarily shaped particles. This approach represents a significant methodological leap in computational granular mechanics by overcoming longstanding limitations in representing complex particle morphology, such as irregularity, non-convexity, surface roughness, and intraparticle voids, while maintaining numerical robustness and computational tractability. Readthis SDF paper.

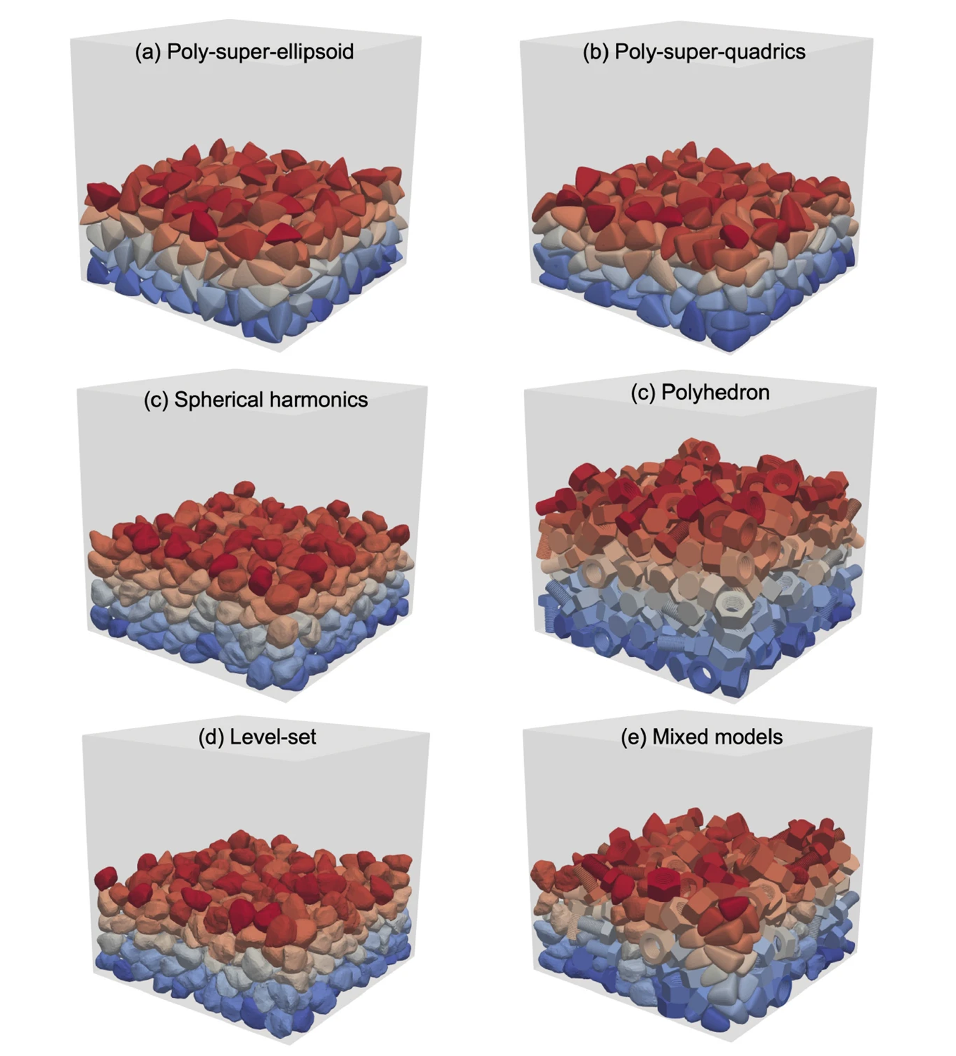

At the core of the framework is the representation of particle geometry via a signed distance function, which maps any spatial point to its signed distance relative to the particle surface (positive inside, negative outside) (see figure above). This generic description enables seamless integration of diverse shape models, including poly-superellipsoids, spherical harmonics (SH), polyhedra, and level sets (LS), under a single computational interface (see figure below). Contact detection is performed using a node-to-surface algorithm, where the surface of one particle is discretized into nodes, and contact is identified when any node intrudes into another particle's SDF field. Crucially, contact forces are derived from an energy-conserving contact theory based on a contact potential defined over intruding nodes. This ensures strict energy conservation during elastic collisions and enhances numerical stability, addressing a key weakness of many ad hoc contact models in existing DEM codes (Readthis CG paper).

SDF-DEM for Arbitrarily Shaped Particles

SDF-DEM particle generation and triaxial compression

SDF-DEM particle generation and triaxial compression

The original contributions of SDF-DEM are threefold. First, the framework unifies disparate particle shape representations within a single, extensible architecture, enabling hybrid simulations that combine different shape models for optimal efficiency and fidelity. Second, it provides a rigorous, physics-based contact formulation that avoids empirical tuning and supports both linear and Hertzian-like force-displacement responses through analytically calibrated potential functions. Third, it enables the direct incorporation of realistic 3D particle geometries, including those with intraparticle voids, as demonstrated in the modeling of coral sand using X-ray CT data. The SH model efficiently captures overall particle morphology, while the LS model accurately resolves internal porosity, allowing systematic investigation of microstructural effects on macroscale behavior. Read this EG paper and the simulated coral sand below.

This mature 3D framework is seamlessly integrated with Constrained Voronoi Tessellation to pack particles into arbitrary containers while controlling size distribution, solid fraction, and fabric anisotropy. A key innovation is the introduction of a shape-fitting parameter that aligns particle morphology with the geometry of its Voronoi cell, enabling dense, facetted packings unattainable with purely random shapes. Together, these series FSD papers form a cohesive pipeline: from experimental image &rarr FD spectrum &rarr statistically faithful 3D particle &rarr controlled packing &rarr physically insightful DEM simulation. This paradigm shifts discrete modeling from idealized abstraction to quantitative, morphology-aware prediction of granular behavior.

SDF-DEM modeling of coral sand packing with inter- and intra-particle porosity

SDF-DEM modeling of coral sand packing with inter- and intra-particle porosity

Invited Technical Review in Nature Reviews Physics

Our original and sustained contributions on particle shape modeling have drawn wide attention. In 2023, Editor of Nature Reviews Physics invited us to write a Technical Review paper titled "The role of particle shape in computational modelling of granular matter".

This review provides a comprehensive overview of computational modeling of granular matter with a central focus on particle shape. The review argues that realistic particle shape is not a secondary detail but a core determinant of mechanical, rheological, and flow behavior across scales, from nanoscale colloids to planetary-scale asteroids.

A key contribution of the Review is the framing of particle shape within broader physical contexts, including crushable and deformable particles, particle-fluid interactions, and large-scale multiscale modeling. The review also highlights emerging frontiers such as the use of machine learning for contact resolution and constitutive modeling, and the need for energy-efficient computing to enable large-scale, high-fidelity simulations. The article serves as an essential roadmap, asserting that the future of predictive granular mechanics lies in the intelligent integration of realistic particle morphology with robust, efficient, and physics-informed computational frameworks.

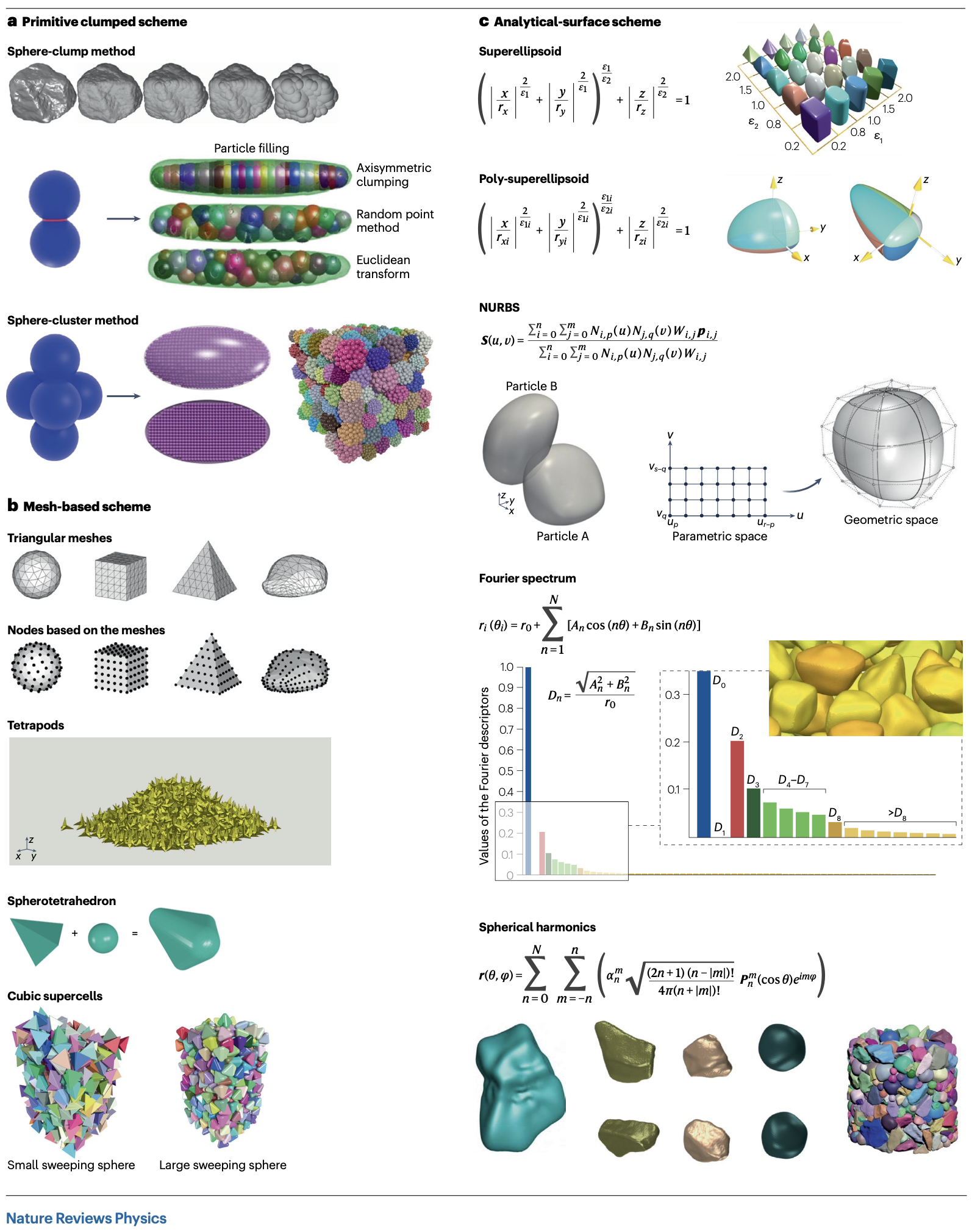

NRP Review on "The Role of Particle Shape in Computational Modeling of Granular Matter"

The Review systematically categorizes major shape representation schemes (see figure below): primitive-clumped (e.g., sphere clusters), mesh-based (e.g., polyhedra), and analytical-surface (e.g., superellipsoids, spherical harmonics). It emphasizes that shape representation is inextricably linked to contact detection and resolution algorithms, which are the computational bottleneck in Discrete Element Method (DEM) simulations.

Read this NRP paper.

#3. Peridynamics for Fragmentation and Crushing

Grain Crushing for Granular Media

Grain crushing is a fundamental process governing granular material behavior across engineering fields from geotechnical design to mining and pharmaceutical processing, yet accurately modeling the transition from intact grains to fragments remains challenging. Traditional Discrete Element Method approaches, while widely used, often oversimplify this complex phenomenon through bonded agglomerates with non-physical parameters or arbitrary particle replacement schemes that fail to capture true fracture physics and natural fragment morphology evolution.

To address these limitations, we employ Peridynamics (PD) to represent each grain as a continuum body discretized into thousands of material points. Unlike finite element methods that struggle with evolving discontinuities, PD naturally handles fracture through progressive bond failure governed by a critical stretch damage model, where bonds break irreversibly when elongation exceeds a threshold derived from the material's critical energy release rate. PD is first used to validate single-particle crushing under varying coordination numbers in a granular assembly. We rigorously compared multiple crushing criteria, including Octahedral Shear Stress and Maximum Contact Force, against high-fidelity PD simulations. The key finding is that the Maximum Contact Force (MCF) criterion is the most robust and simple predictor for particle failure under both uniaxial and multi-directional loading.

Read our Géotechnique paper.

Coupling PD with Physics Engine

Coupled Peridynamics/NCSD modeling of continuous grain crushing

Coupled Peridynamics/NCSD modeling of continuous grain crushing

We then developed a novel multiscale framework coupling Peridynamics (PD) with a Non-smooth Contact Dynamics (NSCD) physics engine, advancing beyond conventional DEM techniques.

The true innovation lies in the coupling protocol bridging these scales: at designated loading intervals, particles are screened using the Maximum Contact Force criterion, and for flagged particles, the exact contact forces from the NSCD simulation are mapped as boundary conditions onto a high-resolution PD model of that single grain. PD handles the fracture of individual particles, while the NSCD engine governs rigid body motions and inter-particle interactions through an impulse-based, constraint-solving approach (see illustration above). This formulation treats contacts as differential variational inequalities solved via iterative methods like Projected Gauss-Seidel, enabling larger timesteps than traditional penalty-based DEM and naturally accommodating irregular polyhedral fragments. Following fracture analysis, broken pieces are identified by clustering connected material points, and a 3D alpha-shape algorithm using CGAL reconstructs watertight polyhedral fragments that preserve realistic morphology including concavity. These fragments then replace the original particle in the NSCD simulation, with the entire process parallelized across multiple CPU threads to make simulations of tens of thousands of crushing events computationally tractable.

Read this CMAME paper.

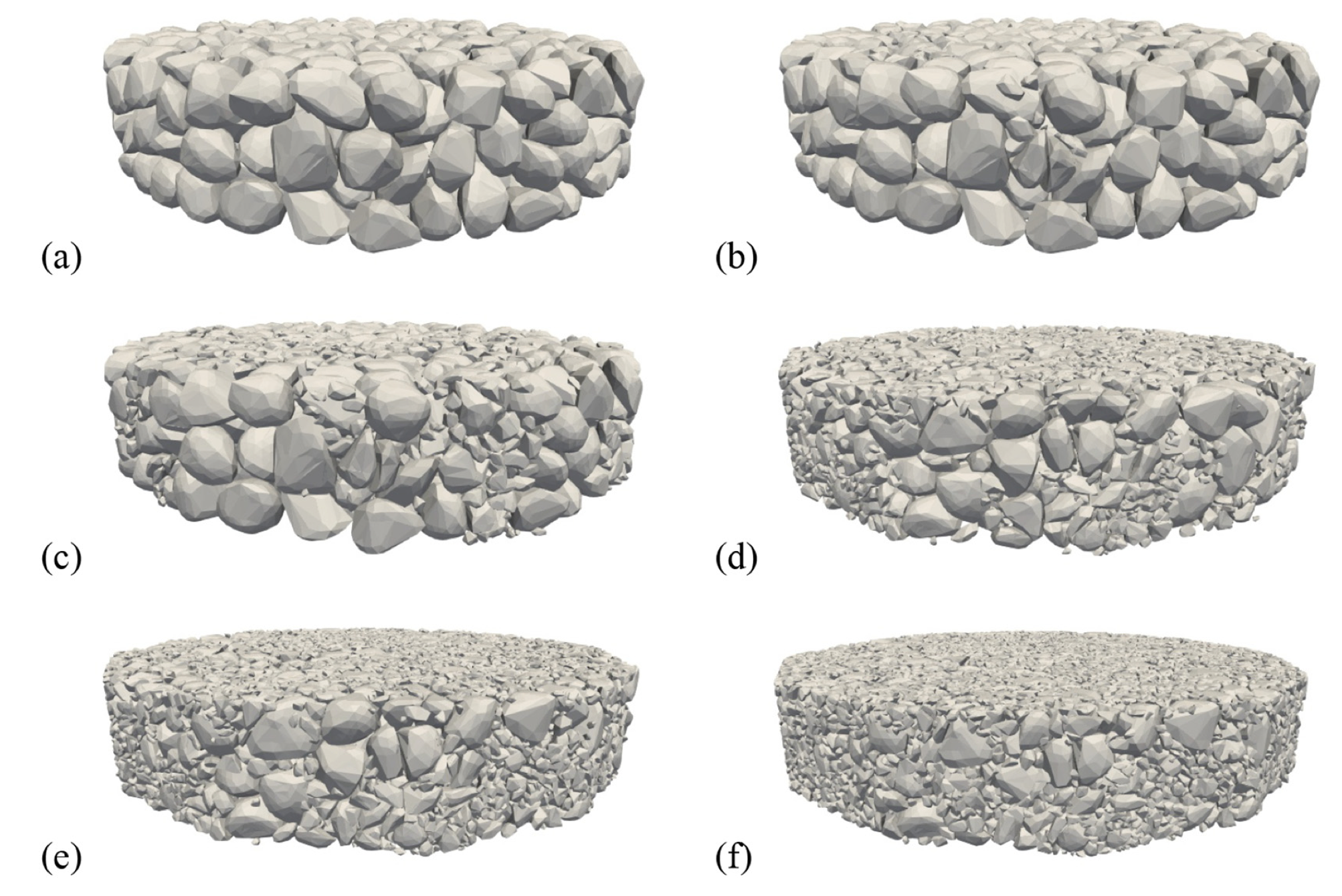

Co-evolution of grain size and shape during crushing

The coupled NCSD/PD framework realistically captures the evolution of both grain size and realistic particle shape, as fragments are reconstructed as polyhedra directly from the fracture surfaces calculated by PD. This provides a more physically accurate representation of the crushing process than methods that replace broken particles with pre-defined clusters of spheres.

It was validated through a simulation of one-dimensional (1D) compression on crushable sand (see above animation). The simulation tracked a sample of 720 particles compressed to 30 MPa, with results closely matching experimental data. Quantitatively, the particle size distribution evolved in line with physical experiments, and the number of particles surged to approximately 27,400. The normal compression line exhibited a slope of 0.52, consistent with analytical studies, and the particle size distribution achieved a fractal dimension of about 2.3, which falls within the typical range for natural sands (see figure below).

Beyond size reduction, the framework provided unique insights into shape evolution. By quantifying particle morphology using the Flatness Index (FI) and Elongation Index (EI) on a Zingg diagram, the simulation revealed that fragments tend to converge toward "spheroidal" shapes, with most particles exhibiting FI and EI values between 0.5 and 1.0. Highly elongated or flat particles were rare, suggesting they are unsustainable under continuous confined crushing. These shape characteristics showed good agreement with available experimental measurements on natural quartz and decomposed granite sands, demonstrating the method's ability to realistically model the intricate coupled evolution of grain size and shape during fragmentation.

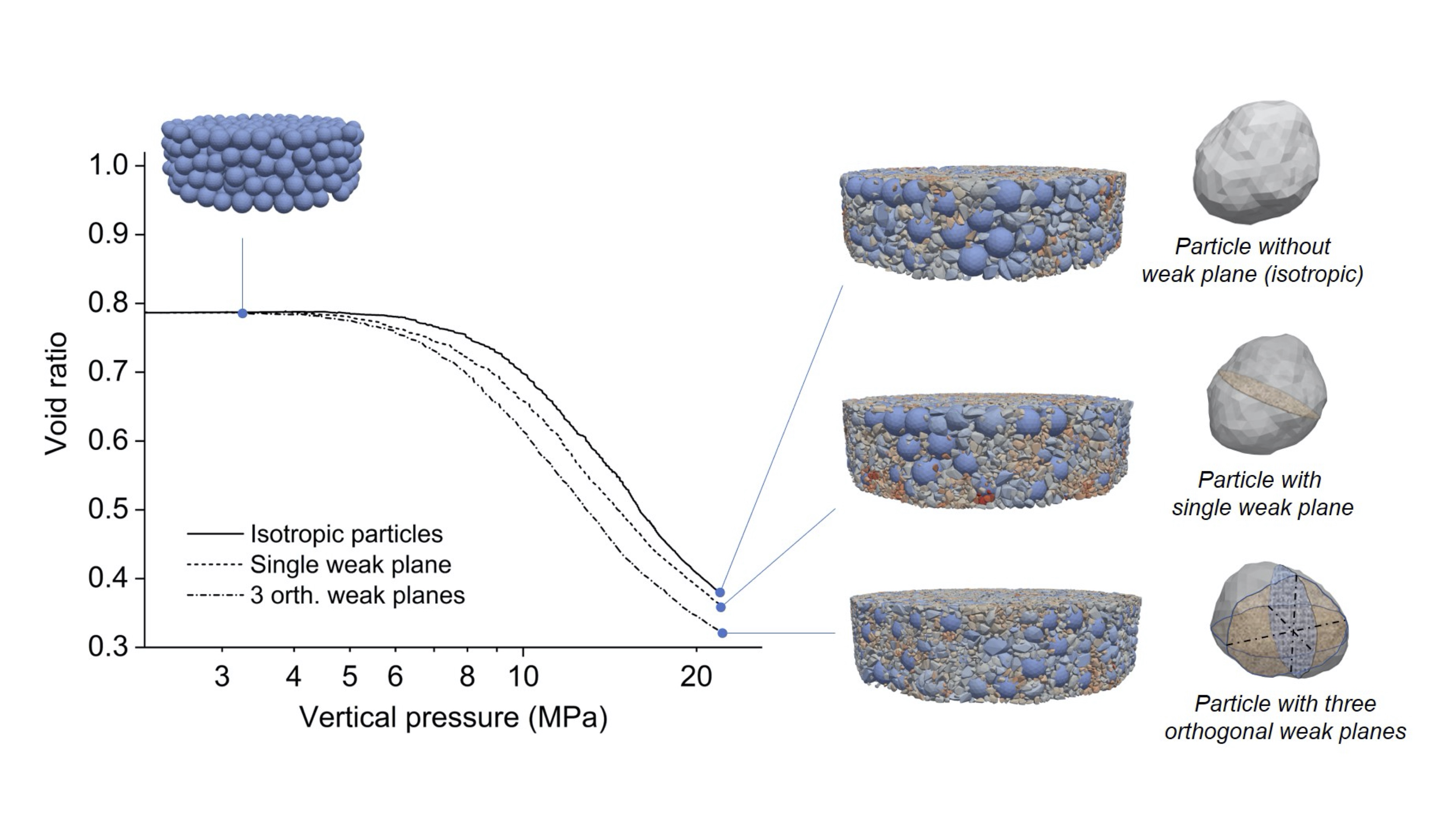

Further Insights into Grain Crushing

Further studies using the hybrid NCSD/PD framework reveal that grain crushing is a complex process involving simultaneous evolution of particle size, morphology and internal structure, with each aspect influencing the other in a continuous feedback loop. The findings show that when particles contain internal microstructural features such as mineral cleavages or planes of weakness, they exhibit fundamentally different crushing behavior compared to isotropic particles. These anisotropic particles fragment more extensively, producing a larger number of fragments and achieving a higher fractal dimension more rapidly. The resulting fragments are generally less spherical and possess lower elongation, flatness, and aspect ratios. Importantly, the presence of such internal weaknesses significantly reduces particle strength and diminishes the influence of external shape on crushing resistance, suggesting that internal structure can override morphological considerations in determining breakage susceptibility. Read this CPM paper.

Regarding particle shape evolution, the research establishes that continuous crushing drives particle shape factors toward unique steady-state distributions, with median values of elongation, flatness, and aspect ratio stabilizing soon after macroscopic yielding. Particle strength exhibits a clear linear correlation with shape, and sphericity emerges as the most effective descriptor for capturing this relationship. Particles with high sphericity are substantially stronger on average and predominantly fail by major splitting, while elongated or flat particles are more prone to asperity breakage. Furthermore, the shape of parent particles strongly influences the shape of their fragments, creating an inheritance effect throughout the crushing process. Read this PT paper.

These insights are made possible by the unique capabilities of the coupled numerical framework. Peridynamics enables physics-based fracture modeling without predefined failure patterns, allowing realistic crack propagation and fragment morphology to emerge naturally from simulations. NCSD efficiently handles complex, evolving polyhedral shapes through complementarity-based contact solving, making large-scale simulations with thousands of irregular fragments computationally feasible. Together, these capabilities enable robust statistical analysis of crushing events, revealing previously inaccessible relationships between particle-scale features and macroscopic granular behavior.

Rock blasting induced fractures by Peridynamics

Novel Peridynamic models have been further developed to simulate dynamic fractures caused by rock blasting. In the study we developed a new non-ordinary state-based peridynamics approach to consider pressure dependency, strain rate effect, and viscoplasticity in rock fracture under blasting, in conjunction with updated Lagrangian peridynamics with Jones-Wilkins-Lee equation of state to simulate detonation of explosives and gas expansion. For detail please reader our paper published in Journal of the Mechanics and Physics of Solids (see also PDF).

Peridynamic

simulation of rock blasting induced fratures in rocks.

Peridynamic

simulation of rock blasting induced fratures in rocks.

Debris Flow Mitigation by Flexible Barriers

Collaborated with government sectors, we have been engaged in developing innovative computational tools to simulate debris flow mitigation by flexible ring barrier. We coupled computational fluid dynamics (CFD) with discrete element method (DEM) to capture the multi-phase, multi-way, multi-physics interactions among the debris solids, the debris fluid and the different deformable components of the flexible ring barrier are captured, including ring-ring and ring-cable frictional contact and sliding. Read our latest paper on this subject.

CFD-DEM

simulation of debris-fluid mixture impacton a flexible barrie

CFD-DEM

simulation of debris-fluid mixture impacton a flexible barrie

Calibration

of CFD-DEM simulation of flexible barrier: rockfall test

Calibration

of CFD-DEM simulation of flexible barrier: rockfall test

We are able to have the same ring flexible barrier subjected to the impact of different geophysical flows which may occur in a natural setting, ranging from dry rock avalanche, debris avalanche, debris flow, debris flood to mud flow, to investigate the impact mechanisms. We found that the transition from pileup to run up mechanisms is found closely related to flow features (including Froude number, solid volume concentration and fluid rheology) and barrier responses (barrier components including barrier net, cables and brakes as well as their coordinated interactions in response to the impact). The insights on the two impact mechanisms and their transitions gained in the study may provide a useful reference for future design of flexible barriers in mitigating hazardous geophysical flows. For detail please reader our paper published in Engineering Geology (see also PDF).

Pileup

mechanism during the impact of

debris flow onto a ring flexible barrier

Pileup

mechanism during the impact of

debris flow onto a ring flexible barrier

Multiscale Modeling in Geomechanics

Coupled

MPM-DEM simulation of large deformation in seabed soil

driven by pipeline drifting

Coupled

MPM-DEM simulation of large deformation in seabed soil

driven by pipeline drifting

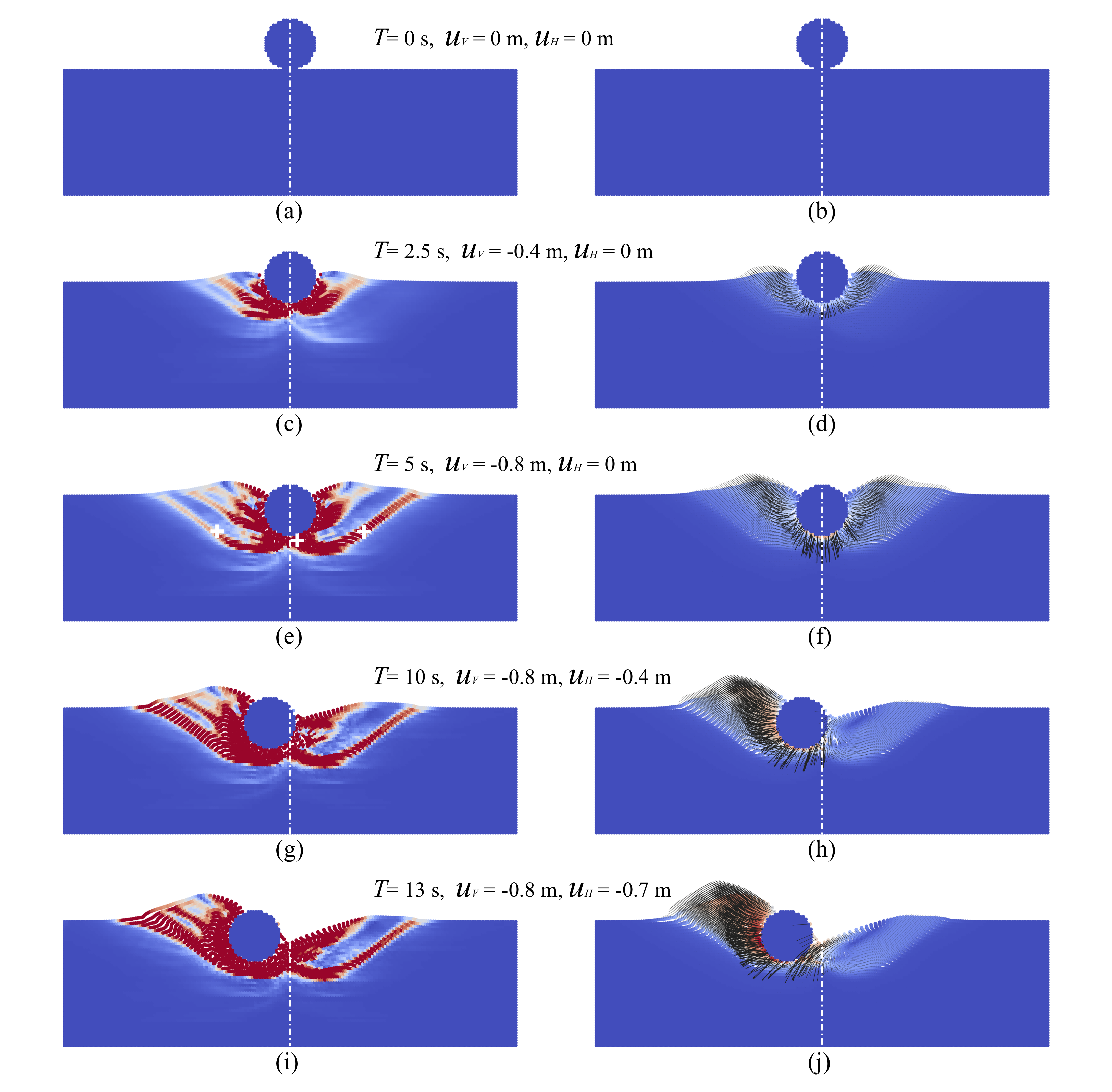

Large Deformation in Geomechanics

Our Lab has developed an innovative computational multiscale modeling framework, based upon FEM/DEM coupling or MPM/DEM coupling, to effectively tackle a wide range of geomechanics boundary value problems to offer cross-scale links between the macroscopic phenomena (such as large deformation, strain localisation, and failures) and their underlying microstructural origins and mechanisms. Large deformation failures in offshore geotechnics are a recent focus of our research (see a MPM/DEM simulation of soil-pipeline interaction in a typical seabed). Read our recent paper on this topic.

A

pipeline settles down before drifting laterally by

wave and pushes large deformation in seabed soil

A

pipeline settles down before drifting laterally by

wave and pushes large deformation in seabed soil

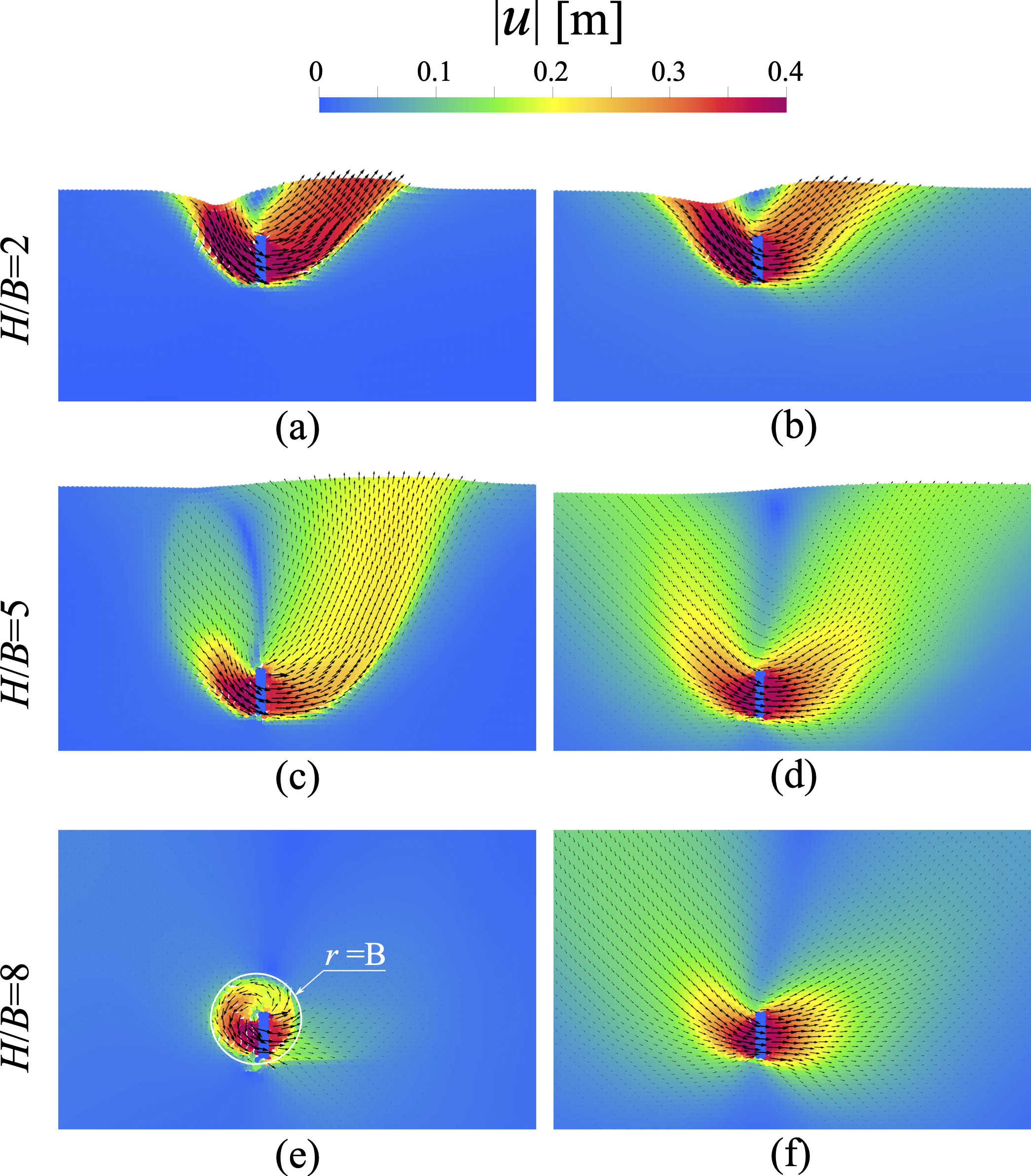

Large deformation in offshore anchor pullout

Multiscale modeling of offshore anchor pullout has been performed to predict the pullout bearing capacity of both horizontally and vertically placed anchor buried in loose and dense sand at different depth. Shown in the following animation are contact force network evolutions for three RVEs (from top to bottom) located behind and immediately in front of the anchor plate and at the edge of the front shear banding, respectively. For detail of the study refer to our paper published in JGGE (see also PDF). The work was a collaboration with Prof. Kenichi Soga of UC Berkeley.

Vertically placed plate anchor pulled

horizontally to the right: evoluation of RVE force

network behind, immediate in front and at

the bottow right of the anchor.

Vertically placed plate anchor pulled

horizontally to the right: evoluation of RVE force

network behind, immediate in front and at

the bottow right of the anchor.

Coupled

MPM-DEM simulation of large deformation around an

anchor during pullout: variation of deformation pattern

with anchor burial depth (H/B).

Coupled

MPM-DEM simulation of large deformation around an

anchor during pullout: variation of deformation pattern

with anchor burial depth (H/B).

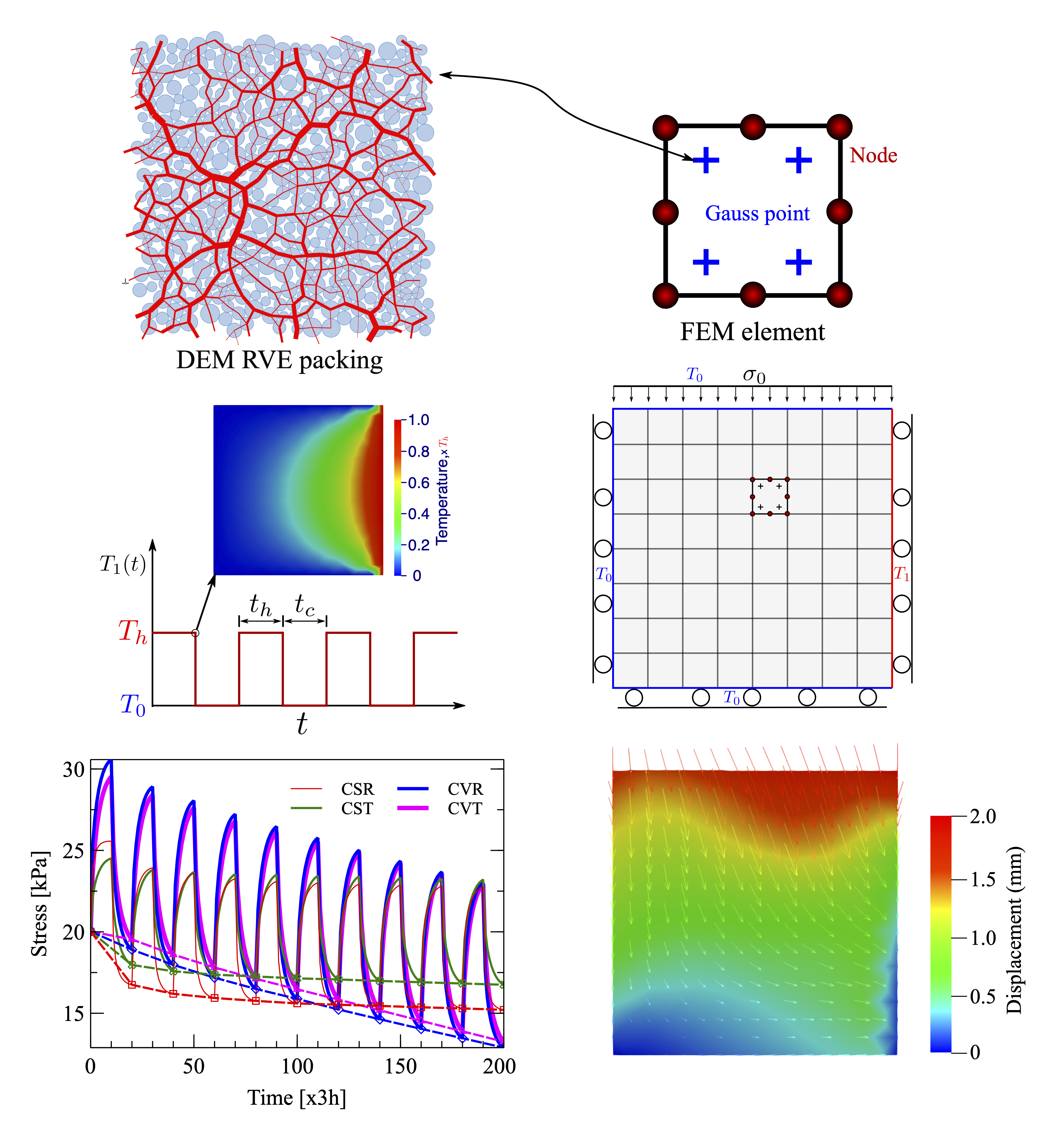

Multiscale modeling of biaxial

shearing of granular media subjected to boundary cyclic

thermal loads

Multiscale modeling of biaxial

shearing of granular media subjected to boundary cyclic

thermal loads

Multiscale modeling of thermo-mechanical coupling

We have further developed a novel multiscale modeling framework to simulate coupled thermo-mechanical behavior in granular media. We employ dual FEMs, one for mechanical and the other for thermal, which share common Gauss points. At each shared Gauss point, we embed a DEM assembly that considers and solve for heat conduction and force transfer at grain contacts to return required variables for the global FEM solutions. Illustrated are animations of the thermal and displacement fields for a biaxially sheared sample subjected to cyclic thermal loading.Read our paper published in Computer Methods in Applied Mechanics and Engineering.

Hierarchical multiscale modeling of

coupled thermo-mechanical behavior in granular media

Hierarchical multiscale modeling of

coupled thermo-mechanical behavior in granular media

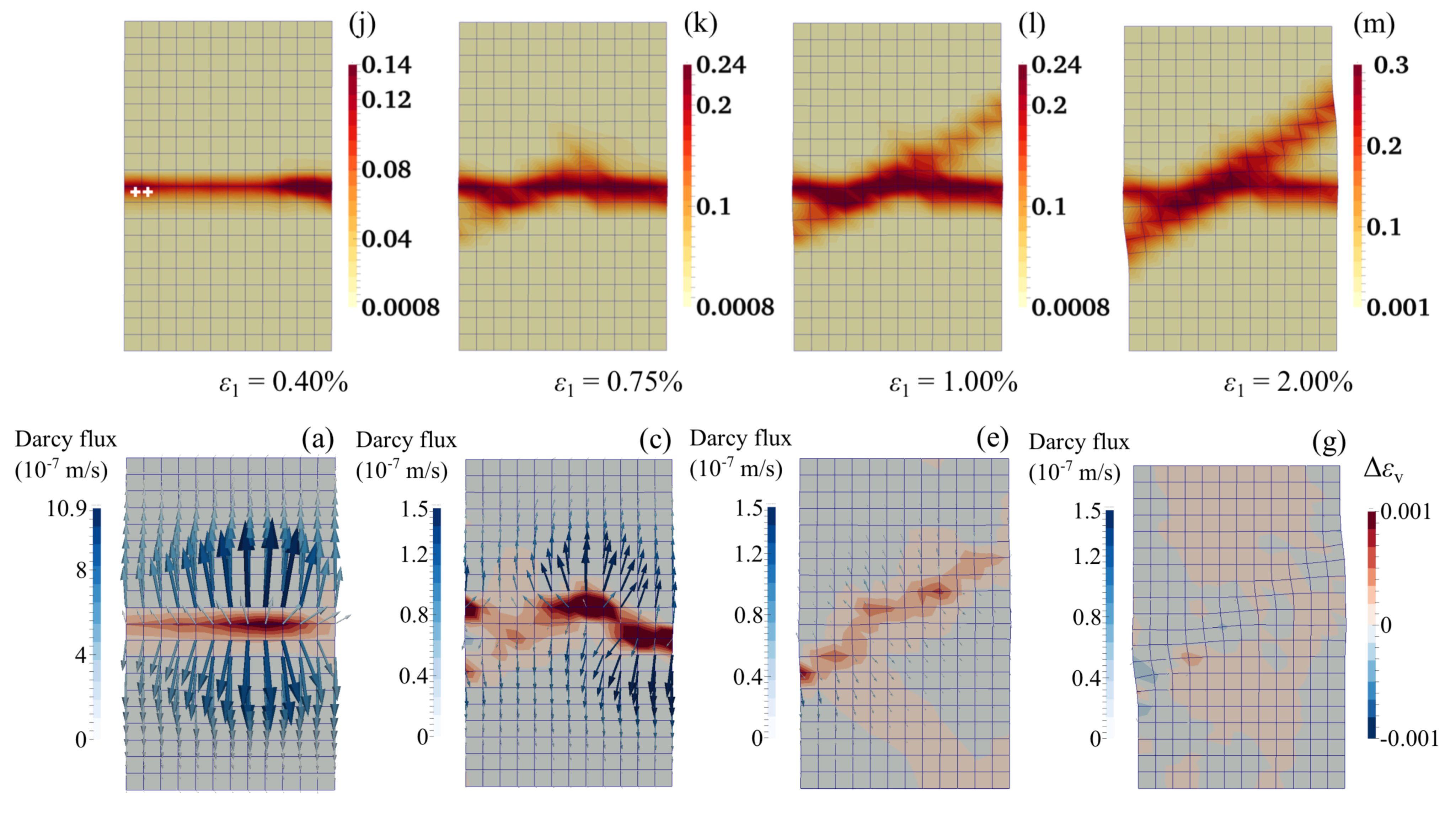

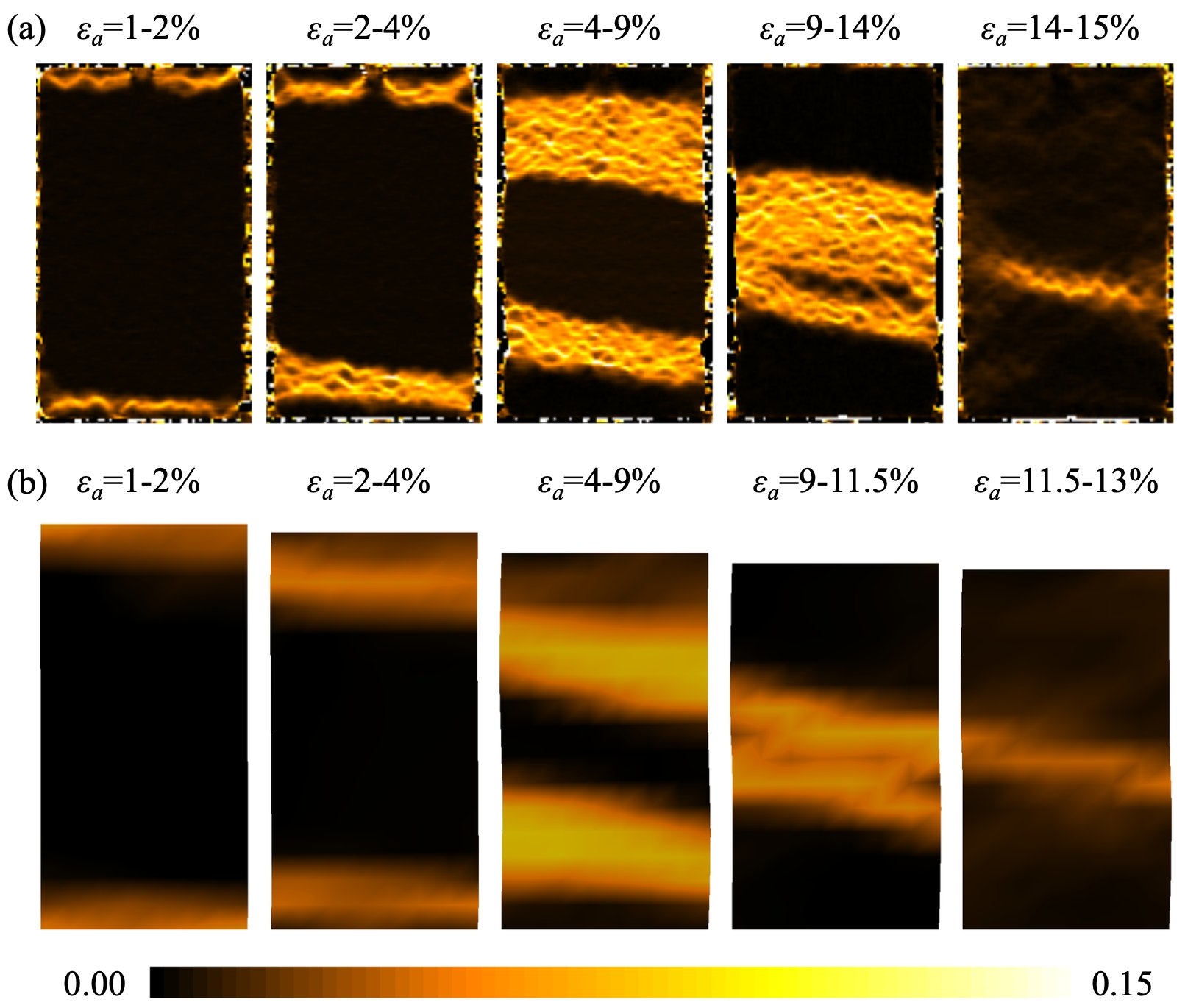

Compaction Front in Granular Rocks

We have further extended the multiscale modeling framework to simulating granular rocks such as sandstone and limestone. We replicated the compaction band in a high-porosity limestone (Tuffeau de Maastricht) observed in X-ray tomography based on coupled 3D FEM/DEM simulations, We confirmed that significant debonding accompanied by collapse of macropores and grain rearrangements may constitute the major microstructural mechanisms causing the formation of compaction bands in high-porosity Tuffeau de Maastricht (Read paper).

We have further performed coupled hydromechanical simulation to show that excess pore pressure can result in transitional evolution of deformation band patterns in saturated sandstone, e.g., from compaction band to shear band as shown above. Read our paper published in Engineering Geology.

Multiscale modeling of

hydro-mechanical coupling during the formation of

compaction bands in high-porosity sandsone

Multiscale modeling of

hydro-mechanical coupling during the formation of

compaction bands in high-porosity sandsone

Herarchnical multiscale modeling of

evolaution of compaction front in Tuffeau de Maastricht

(a porous limestone) in comparison with X-ray CT data

Herarchnical multiscale modeling of

evolaution of compaction front in Tuffeau de Maastricht

(a porous limestone) in comparison with X-ray CT data

Constitutive Modeling of Granular Sand

(To be updated) We focus on anisotropic critical state of granular soils and develop advanced constitutive models centered on the use of fabric tensor and fabric evaluation to describe both quasi-static and cyclic behavior of granular sand.